Apple has unveiled a major manufacturing milestone, announcing that all Apple Watch Ultra 3 and titanium Apple Watch Series 11 cases are now produced using 3D-printed, 100% recycled aerospace-grade titanium powder — a feat once considered impossible at scale.

What began as a speculative idea has evolved into one of Apple’s most ambitious engineering achievements yet.

“It wasn’t just an idea — it was an idea that wanted to become a reality,”

says Kate Bergeron, Apple’s vice president of Product Design.

“We had to prove, with continuous prototyping, process optimization, and a tremendous amount of data gathering, that this technology was capable of meeting the high standard of quality we demand.”

A Leap Forward in Sustainable Manufacturing

This breakthrough forms a major pillar of Apple 2030, the company’s commitment to achieving carbon neutrality across its entire footprint by the end of the decade. The new 3D-printing process cuts raw titanium use by 50% compared to previous generations, enabling Apple to save more than 400 metric tons of titanium this year alone.

“At Apple, every team holds environment as a core value,”

says Sarah Chandler, vice president of Environment and Supply Chain Innovation.

“We knew 3D-printing was a technology with so much potential for material efficiency.”

The shift to additive manufacturing allows parts to be printed close to their final form, minimizing waste inherent in traditional subtractive machining. The result: more efficient production with less environmental impact — without sacrificing durability, aesthetics, or performance.

Engineering at Extreme Precision

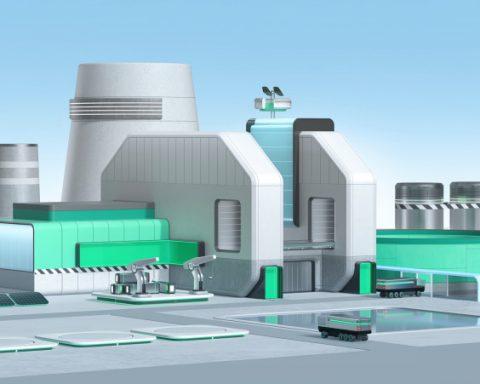

The journey to scale 3D-printed titanium involved years of experimentation across materials science, software, and hardware engineering. Inside Apple’s manufacturing facilities, rows of towering 3D printers work continuously, each machine using six lasers to build a watch case layer by layer — more than 900 layers in total.

Before printing begins, titanium is carefully atomized into powder with extremely low oxygen content to prevent reactivity. “This was cutting-edge materials science,” Bergeron explains. The powder must be exactly 50 microns — as fine as sand — while each printed layer is precisely 60 microns thick.

After printing, operators remove excess powder, cases are separated using a wire saw in a process called singulation, and each enclosure undergoes automated inspection to verify its dimensions and cosmetic integrity.

“The mechanical engineers have to be the most skilled puzzle solvers in the entire world,”

says Bergeron.

“They take the circuitboard, display, battery — everything — and make them fit perfectly while meeting our reliability goals.”

Breakthroughs Beyond the Watch

3D-printing unlocked design possibilities that were previously impossible with forged metal parts. Apple improved waterproofing on cellular watch models by printing textures inside the case, allowing plastic antenna components to bond more effectively with titanium.

The innovation has already expanded beyond the Watch. Apple’s new iPhone Air uses a 3D-printed titanium USB-C port enclosure built with the same recycled powder, allowing for an ultra-thin yet durable design.

A New Era of Materials Innovation

For Apple, this advancement represents more than a manufacturing upgrade — it signals a systemic shift toward more sustainable production across the industry.

“We’re extraordinarily committed to systems change,”

Chandler says.

“Our North Star has always been to design products that are better for people and planet.”

Bergeron agrees:

“Now that we’ve achieved this breakthrough at scale, in a truly sustainable way — the possibilities are endless.”

With its fusion of design excellence, material science, and environmental responsibility, Apple is charting a future where high-performance technology and sustainability not only coexist, but elevate each other.