SuperMeat, a pioneering food-tech company based in Tel Aviv, is gaining momentum in the race to bring lab-grown chicken to global consumers — and its latest advances may bring that goal closer than ever.

Founded in 2015, SuperMeat develops poultry meat directly from chicken cells, combining the expertise of food technologists, biologists, engineers, and chefs in a joint effort with the meat industry to create a high-quality, sustainable alternative to conventionally farmed chicken. supermeat.com+2supermeat.com+2

A Breakthrough in Cost and Scale

On November 7, 2024, SuperMeat announced a major cost milestone: it has reduced the production cost of its cultivated chicken to US$11.79 per pound when produced at scale — a price comparable to premium pasture-raised chicken in the United States. PR Newswire+2Food Business Middle East+2

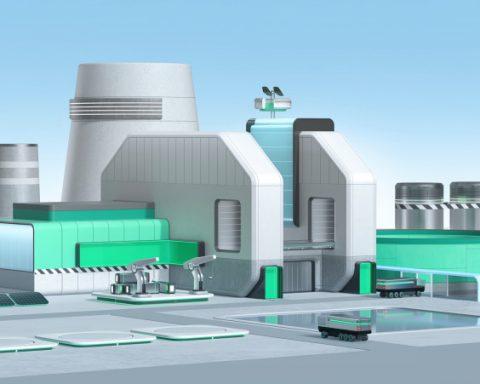

The company achieved this by optimizing its cell-culture process. Its cell line reaches 80 million cells per milliliter in just nine days, and it no longer relies on animal-derived growth serum, which has historically been a major cost driver. PR Newswire+2Food Business Middle East+2

Moreover, SuperMeat’s technology allows it to produce fat in only 24 hours, and muscle tissue in just four days — enabling a faster and higher-yield production cycle. 0search7

By using embryonic stem cells, they generate both muscle and fat directly, and the cells are nearly double the size of typical ones, which helps cut costs by nearly half.

Sustainable and Animal-Friendly

SuperMeat says its method uses far fewer resources than traditional chicken farming. Its closed, controlled bioreactor systems save land, water, and energy, and eliminate the need for antibiotics — all while delivering consistent, high-quality meat.

In addition, because production happens in a sterile environment, the resulting product has a longer shelf-life and reduced risk of contamination.

Industry Firsts and Taste Validation

SuperMeat opened a pilot “farm-to-fork” facility called The Chicken, where diners can actually watch the production process through glass walls — a transparency move that underscores its mission.

In January 2022, the company hosted an industry-first blind tasting of cultivated vs. conventionally-raised chicken, and judges—including food experts—found the two nearly indistinguishable in taste, texture, and aroma.

Regulatory and Market Moves

SuperMeat has also drawn support from the Israeli government: it secured a grant from the Israeli Innovation Authority to build an open-source high-throughput system to screen feed media components, with the goal of reducing costs for the entire cultivated-meat industry.

To help scale its supply chain, SuperMeat has partnered with global food biotech firm Ajinomoto, and signed a memorandum of understanding with PHW Group, one of Europe’s largest poultry producers.

Cultural and Ethical Milestones

Notably, SuperMeat’s cultured chicken has also been certified kosher by the Orthodox Union, the largest kosher certification body in the United States. This development could open the door for lab-grown meat to more consumers in religious communities that observe dietary laws.

Looking Ahead

For SuperMeat, the cost breakthrough isn’t just a technical win — it’s a major step toward commercialization. The company projects that, once its continuous bioreactor process is scaled up, it could produce up to 3 million kilograms (about 6.7 million pounds) of cultivated chicken per year — equivalent to nearly 2.7 million conventional chickens — while reducing land use dramatically.

With rising global demand for protein and growing pressure to reduce the environmental impact of animal agriculture, SuperMeat’s innovations may resonate far beyond Israel.